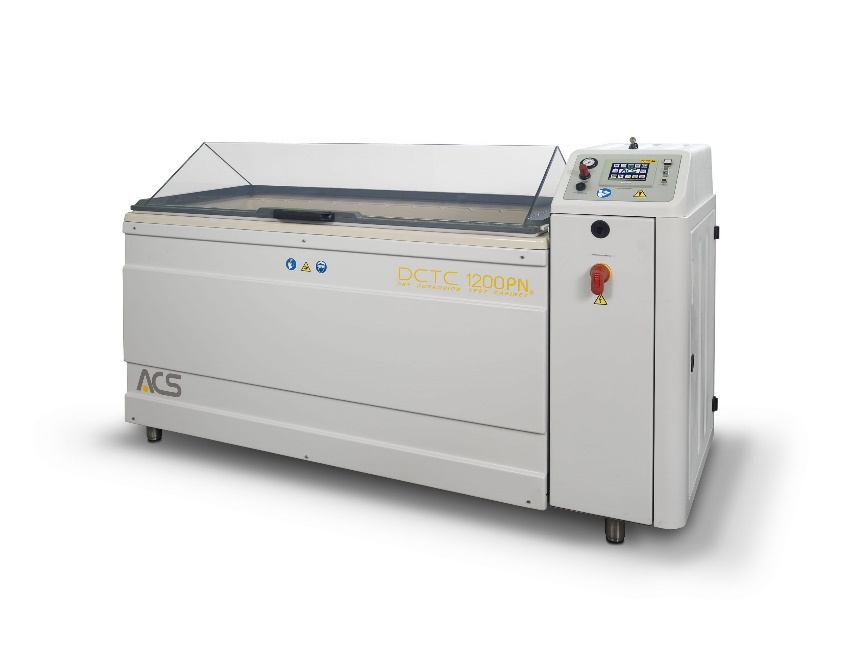

Manufacturer: Angelantoni / Origin: Italia

Climatic chambers for corrosion testing can help predict the resistance of materials in order to estimate the life cycle of the components, compare different products and evaluate the behavior of a coating in a specific corrosive environment.

Specifications:

| Model: DCTC1200 PN |

| Useful capacity with hood approx: 1105 |

| Internal dimensions approx. (mm): 1700x640x810 |

| External dimensions approx. (mm): 2280x830x1320 |

| Temperature Range (°C): amb. …+55 |

| Rated power (kW): 4 |

| Rated current absorption (A): 18 |

| Weight (without packing) (kg): 220 |

| Supply voltage (Vac): 230V ±10% 50Hz 1+G |

A dry corrosion test chamber is a type of environmental testing equipment that is used to assess the corrosion resistance of materials and coatings under dry conditions. The chamber typically consists of a sealed enclosure in which test specimens are placed, along with a controlled atmosphere and temperature control systems.

During testing, the chamber is filled with a dry gas such as nitrogen or air, and the temperature and humidity levels are controlled to create a specific testing environment. Test specimens are then placed inside the chamber and exposed to the controlled environment for a set amount of time.

Dry corrosion test chambers may use a variety of test methods to assess the corrosion resistance of materials, including salt spray testing, cyclic corrosion testing, and exposure to corrosive gases such as sulfur dioxide or hydrogen sulfide.

The results of dry corrosion testing can provide valuable information on the durability and corrosion resistance of materials and coatings, and can be used to inform material selection and design decisions in a range of industries, including aerospace, automotive, and manufacturing.

Overall, dry corrosion test chambers are essential tools for researchers, engineers, and quality control professionals who need to assess the corrosion resistance of materials and coatings in dry environments.